Alternate Finishing meets the industry's most demanding requirements for specialty finishes on printed wiring boards. Our primary specialties include:

ENIG Fully automated 6-8% phosphorous electroless nickel, immersion gold plating line, with panel size capabilities up to 26" x 30".

Nickel Gold Fully Automated electroplated nickel and gold with panel size up to 54" x 36"

Sulfamate nickel plating baths (low stress) with panel size capabilities of 24" x 30"

Soft wire bondable gold plating baths with panel size capabilities of 24" x 30"

Hard gold plating baths with panel size capabilities of 24" x 30"

Immersion Silver solderable final finish for printed circuits

Thin Film

Two Soft wire bondable gold plating baths

Sulfamate Nickel plating

Copper Sulfate plating

Quality Assurance

Fisherscope X-ray system, measuring plating thicknesses.

Oxford Instruments CMI900 XRF system to measure plating thickness

10X stereo zoom microscope

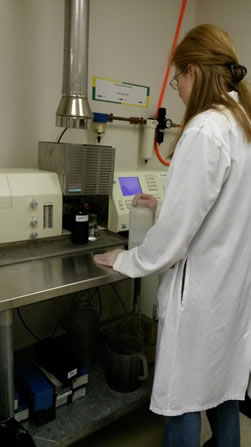

Chemical Analysis Lab

An Atomic Absorption Spectrophotometer is used for process control and determining if solutions are nearing their end of life.

We have the ability to perform chemical analyses related to our processes.

Technical Support

Besides sending in orders of mature designs for plating, customers can tap into the deep expertise and know-how at Alternate Finishing. Plating appears to be simple, yet it is governed by dozens of standards and amendments, that are not easy to navigate. Many product failures can be traced to specifying the incorrect coating.

Alternate Finishing routinely participates in R&D with customers to develop the most robust and cost-effective products, and gives advices to improve existing designs as product evolves. We also help with defect trouble shooting and failure investigation.